distribute worthwhile and interesting information to help industry generate more profit.

The key to big success is timing. While in the concept stage, OEM’s are experimenting with designs – designs that can create a life sentence of satisfaction or great frustration on the factory floor.

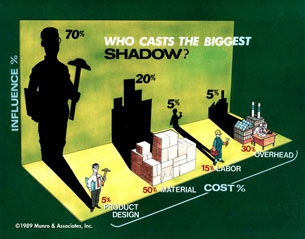

Design is the most critical step and the driving force in the manufacturing process. The proof is in the analyses of the product’s total manufacturing cost, as illustrated in the Shadow Chart diagram. Product design may only account for five percent of a product’s total cost, but it dictates seventy percent of the product’s total cost. Therefore, it becomes critical that designs are done right, the first time.

While in the concept stage, designs can be modified easily with a stroke of a pen and few mouse clicks. Changes are rapid and relatively inexpensive. If additional changes are needed after the design is complete, one must consider all of the downstream activities, which may be affected, such as performance testing, assembly and checking fixtures, secondary tools and production tooling.

Click here to read more about getting things right the first time

Each issue of The Munro Report will feature one of Munro's Design Principles. Implementation of these principles will help maximize the profitability of your product through its design.

#2 Minimize The Number Of Parts By Mike Pritchett

“The best part is no part at all” – Sandy Munro

A part that does not exist does not need to be designed, engineered, manufactured, purchased, shipped, tracked or assembled. A part that does not exist can not fail or wear out and will never need to be inspected or replaced. Reducing the number of parts in a product is one of the best ways to ensure quality, value and profit for your organization.

By using the Munro & Associates' Part Value Challenge at the design phase of your product, you can eliminate the cost associated with unnecessary parts. If a part does not need to move relative to other parts in the assembly or if the part does not need to be a fundamentally different material, it should be eliminated from the design.

Electrical components whose functions can be combined within other components, components that require manual soldering and components that could utilize surface mount technology are also candidates for elimination.

Holding the above requirements for each part in an assembly will eliminate the “Poor Quality Drivers," fasteners, springs, belts and chains, wires and electrical connectors. Eliminating ALL of these components from a design will not always be possible, but determining which parts to target will serve as a guide for improving your design. A creative approach is required to eliminate as many extraneous or “slave” parts as possible from the assembly and to ensure the simplest, highest quality and most profitable design for your product.

Generally during the first week of April here in Michigan we’re thinking more about finally being able to put the snow shovels away than planning for the next Christmas holiday season. Not the case with two of our Benchmarking and Information Center (BIC) based employees. Janice Larson together with Jackie Ludwig are already thinking about how they’re going to share their enjoyment of crocheting and helping those less fortunate this year.

What started out four years ago as a personal task by Jan & Jackie to provide some needy children gifts they could give to their Moms at Christmas (Jackie had just learned how to crochet that year) has grown to be a similar yearly endeavor for these two ladies. You would think that two

working women with families of their own (including a daughter that’s getting married this year) wouldn’t have time to do much of anything extra, but just about daily, all year long, you’ll find one or both of them at the lunchroom table with skeins of yarn making something.

One year it was making baby blankets and matching booties for women with very young children at the Pontiac (Michigan) Women’s Rescue Mission. These were combined with other infant care sundries (soaps/lotions/baby powder, etc.) into welcome baskets for the residents. We’re told that much too often these women show up at the shelter with their children in tow and only the clothes on their backs. The previous year Jan made wool scarves and hats for a local church that was sheltering a group of homeless adults during the holidays.

To the bunch of guys at the BIC (the writer included) that watch these two effortlessly crocheting away after lunch, while holding a conversation, the task is just this side of miraculous. To Jan and Jackie it’s an enjoyable way for each of them to give back to our community. They’re already discussing this year’s project, perhaps making lap robes as gifts for the residents of a local nursing home.

To request more information about Munro and Associates, Inc. Click Here

All photos and information copyright Munro & Associates, Inc. 2008